Air Bearing Spindle Design

Air bearings are also a common component in high speed equipment. ABL remain at the forefront of air bearing spindle technology for your Micro machining dicing and precision rotation requirements.

What Is An Air Bearing Celera Motion

High speed Figure 3.

. Analysis on discharge coefficients in FEM modeling of hybrid air journal bearings and experimental validation. We specialise in the design and manufacture of air bearing spindles for use in precision manufacturing equipment within the printed circuit board PCB micro machining dicing and other high-specification industries. Table 1 is the spindle specifications required by spindle user.

4B BLOCK-HEAD air bearing spindle. The Naiver Stokes equation governs the air bearing used in this spindle design. Ad Wide Selection of Industrial Controls from Timken.

The thought was to feed air to it and convert it to an air bearing spindle. Advanced design analysis and modern manufacturing techniques combine to make ABL the supplier of choice for reliable and cost effective air bearing solutions. By simplifying this governing equation mass flow rate is obtained as follows.

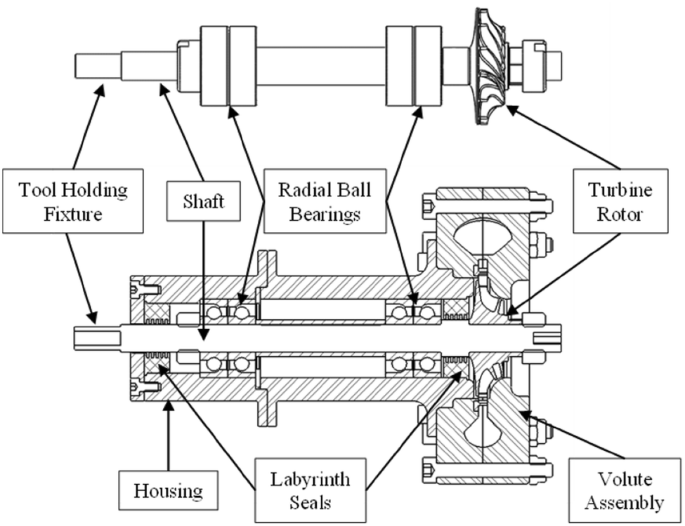

Radial air bearing Figure 5. Site Design by Chris Reich TeachU. MACHINE TOOL SPINDLE BEARING SELECTION MOUNTING GUIDE 1.

New Way Air Spindles are an exceptionally low flow technology taking almost six hours to push one cubic meter of air through a 50mm x 100mm bearing and thus are extremely efficient in operation when compared to orifice-based systemsIf airflow is somehow disrupted to the air bearing the porous nature of the bearing surface means depressurization will occur. Ad Order today with free shipping. Air bearings represent the next logical step in bearing design.

Song L Cheng K Ding H et al. It seems like a circumferential groove where the air feed is with a linear feed groove to another or possibly a third circumferential groove would work. Get the Deals now.

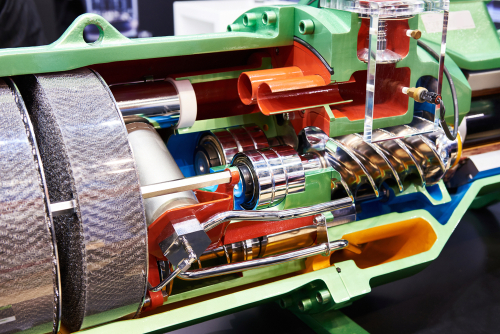

New Way Air Bearings 50 McDonald Blvd. These orifice-compensated air-bearing spindles use a single piece of 440 CSS shaft and thrust plate with 660 bearing bronze journal providing a proven robust and forgiving design. The choice of air bearings was a design decision weighing the advantages of aerostatic systems at smaller speeds compared to hydrodynamic plain bearings.

Design a spindle with high accuracy and stiffness at speeds up to 10000 RPMs with low air consumption liquid cooling and balancing adjustments all packed into a small overall footprint. Our patent pending OAV Thrust Air Bearing is a breakthrough innovation in air bearing industries. 1 510 887-2647.

The Naiver Stokes equation governs the air bearing used in this spindle design. Company News Updates. Superior Mechanical Design The ABS2000 utilizes a precision ground air-bearing to.

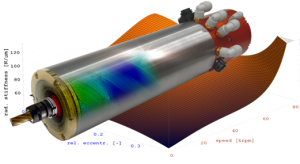

A segment of the bearing cylinder may be omitted resulting in an open radial pad. 10 m a h 3 p 1 2 p 2 2 24 ηRT 1 ρνA where a is length that is 0074 m ℎ represents the height of the air-bearing film between the bearing and the shaft and is equal to 000001143 m p 1 is the pressure at the. Air bearings in general have a proven track record having been employed in coordinate measuring machines for 20 years.

An air bearing surface is formed between a cylindrical shaft and a mating air bearing bushing. We produce Air Bearings and Custom Machined Items to your specification. Allied is the Distributor of Choice for Industrial Automation Control.

Click to download the SP138 Datasheet. Is there a standard design on how to put air passages in the housing to distribute the air around and along the spindle. This is also an experiment in improving tool change precision by having the tool be integrated into an easily removable spindle a solution not easily possible with lubricated bearings.

PIs US operation has extensive experience with the design and manufacture of Air Bearing precision positioning products. The resulting linear and rotational motion is a cost effective solution. Covid-19 RESTRICTIONS 23.

Available in a variety of sizes and speeds with a flange foot or a-thermal mounting. Designed and manufactured for many advanced industries including printed circuit board semiconductor manufacturing high volume automotiveindustrial coating and precision machining glass composites and metalsStandard and customised spindle designs are available as well as complete manufacturing solutions for. High Precision Angular Contact Ball Bearings - RobustShot Series Direct oil-air lubrication in order to achieve highest speeds.

The many technical advantages of air bearings such as near zero friction and wear high speed and high precision capabilities and no oil lubrication. The result was the Model SP138 High Speed Air Bearing Spindle. These two spindles are designed for i woodworking industry for routing applications and for ii high-speed light metal milling applications.

OAV Thrust Air Bearings run on a standard size shafting fix and maximizes stiff motion with precision. GHUS Air Bearing Spindle. Here we present two design cases of air-bearing spindles to explain the computer-aided design procedures of the system.

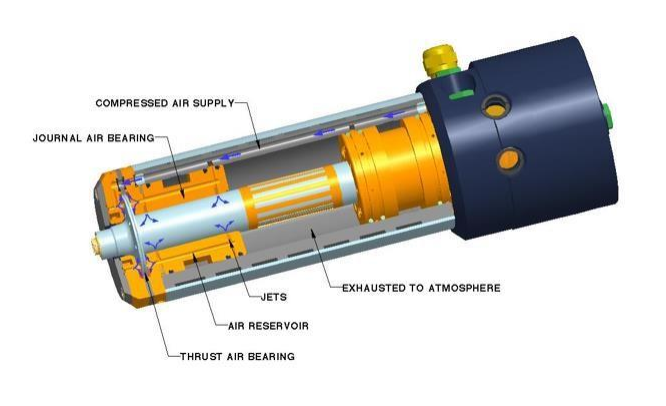

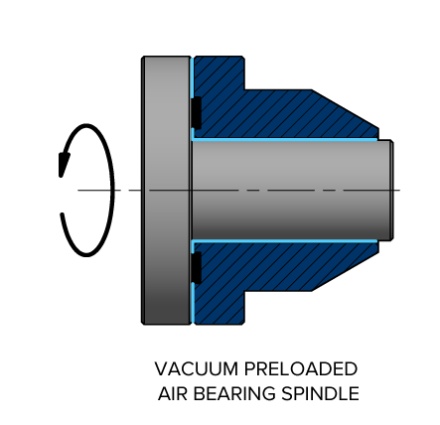

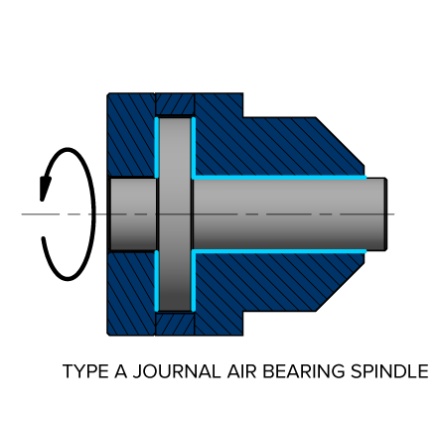

Because of their minimal wear and smooth operation high speed machines can practically run indefinitely. Air Bearing Spindles Basic Principles The construction of a typical high speed air bearing is shown below in Figure 4. Typical applications for our spindles are in drilling routing grinding cutting and polishing of various materials such as.

By simplifying this governing equation mass flow rate is obtained as follows. Contact Air Bearing Technology Phone. High-Speed Air Bearing Spindle Aerotechs ABS series direct-drive air-bearing spindles were designed to provide superior angular positioning and velocity control for applications including data storage wafer processing diamond turning and imaging.

THRUST AIR BEARINGS BUSHINGS. For the first time an air bearing is available that fully integrates and works on three-way frictionless surface. Optimum ball bearing design results in lower rotational torque.

In this particular design the axial or thrust bearing is located at the front of the spindle and is integrated into the front radial journal bearing. Dovetail air bearing slide Figure 4. PI is building on over 200 years of in-house air bearing experience to offer linear planar XY and rotary air bearing stages.

The worlds market-leading high-speed air bearing spindles. As the industries we serve have matured requiring more durable air bearings with non repeatable run out at nano-meter levels Air. Air Bearing Technology utilizes a unique spherical air bearing spindle design.

SINGLE-AXIS ROTATING AIR BEARING SPINDLES. This design has been selected over other configurations due to inherent positive qualities such as performance and reliability.

Air Bearing Spindles Ultimate Performance Abtech

Structure Of Air Bearings Download Scientific Diagram

Jaeger Air Bearing Spindle Youtube

Unique Selling Propositions Of The Products Levicron Gmbh

Spindles 101 New Way Air Bearings

.png)

Why Cnc Machining With Aerostatic Tool Spindles Is Becoming A Global Phenomenon

Design And Development Of A High Efficiency Air Turbine Spindle For Small Part Machining Springerlink

Mini Mill Spindle Concepts And Design

Air Bearing Spindles Ultimate Performance Abtech

Air Bearing Spindles Air Bearing Technology

How Air Bearings Work Loadpoint Bearings

How Air Bearings Work Loadpoint Bearings

A Assembly Of The Current Air Driven Atomizer Spindle B Fluid Download Scientific Diagram

Alfred Jager High Performance Spindles Luftlagerbuchsen Air Bearings Systems Youtube

Cross Sectional View Of An Air Bearing Spindle 41 Download Scientific Diagram

Designing And Building A High Speed Air Bearing Spindle Youtube

Komentar

Posting Komentar